PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

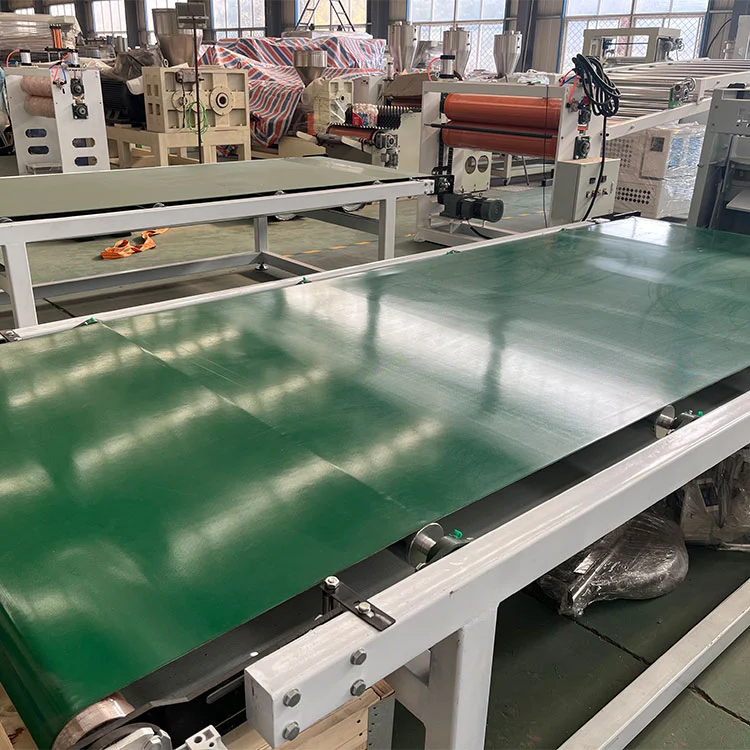

In the competitive landscape of plastic machinery, Qingdao Eaststar Plastic Machinery Co., Ltd. stands out with its innovative ABS Double-layer Co-extrusion Board Machine. This state-of-the-art equipment is engineered to produce high-quality, durable ABS boards with two distinct layers, offering superior performance for various industrial applications. By seamlessly integrating advanced co-extrusion technology, this machine ensures consistent output, making it an indispensable asset for manufacturers aiming to elevate their product quality and operational efficiency.

ABS Double-layer Co-extrusion Board Machine Overview" />

ABS Double-layer Co-extrusion Board Machine Overview" />

The ABS Double-layer Co-extrusion Board Machine from Qingdao Eaststar brings a host of benefits that set it apart. Its robust construction guarantees longevity, while the precision engineering minimizes material waste. With features like automated control systems and energy-efficient components, users experience smoother operations and reduced downtime. The machine's ability to produce boards with enhanced strength, weather resistance, and aesthetic appeal means your end-products meet the highest standards, whether for automotive parts, construction materials, or consumer goods.

Many manufacturers face issues like inconsistent board thickness, high production costs, and limited customization. Qingdao Eaststar's machine tackles these head-on with intelligent design and reliable performance. For instance, the co-extrusion process allows for tailored layer properties, solving the problem of balancing durability and flexibility. Below is a parameter table highlighting key specifications that address common pain points:

| Parameter | Specification | Benefit |

|---|---|---|

| Production Capacity | Up to 500 kg/h | High output for large-scale projects |

| Layer Thickness Control | ±0.1 mm precision | Eliminates uneven surfaces |

| Energy Consumption | Optimized at 15% less than competitors | Lowers operational costs |

| Material Compatibility | ABS and hybrid polymers | Versatile for diverse applications |

This machine is tailored for businesses in sectors such as packaging, automotive manufacturing, and building materials. Whether it's creating lightweight yet sturdy panels for vehicle interiors or producing weather-resistant boards for outdoor structures, the ABS Double-layer Co-extrusion Board Machine adapts to diverse needs. Its versatility makes it a go-to solution for startups and established enterprises alike, enabling them to innovate and expand their product lines with confidence.

Users of Qingdao Eaststar's machine often report a significant boost in productivity and a reduction in material defects. Imagine the satisfaction of delivering flawlessly finished boards that exceed client expectations, all while cutting down on waste and maintenance hassles. This machine doesn't just manufacture products; it builds trust and reliability, empowering businesses to tackle complex projects with ease and pride.

Compared to standard extrusion machines, Qingdao Eaststar's model incorporates dual-layer technology that allows for customized material combinations, such as a tough outer layer and a flexible inner core. This unique approach enhances product performance without compromising on efficiency. Additionally, the machine's user-friendly interface and remote monitoring capabilities provide an edge in today's smart manufacturing environment, ensuring you stay ahead of the competition.

What is the typical setup time for this machine?

The machine is designed for quick installation, usually taking 2-3 days with professional guidance, thanks to its modular components and comprehensive manual.

Can it handle recycled ABS materials?

Yes, it supports up to 30% recycled content without sacrificing quality, making it an eco-friendly choice for sustainable production.

How does the co-extrusion process improve product quality?

By combining two layers, it allows for properties like UV resistance and impact strength to be optimized separately, resulting in more durable and versatile boards.

What kind of maintenance is required?

Routine checks every 500 hours of operation are recommended, focusing on cleaning and part inspections to ensure long-term reliability.

Is training provided for operators?

Qingdao Eaststar offers detailed training sessions and online resources to help your team master the machine quickly and safely.