PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

When it comes to plastic machinery, Qingdao Eaststar Plastic Machinery Co., Ltd. stands out with its unwavering commitment to quality and innovation. Today, we proudly present the PVC Door Curtain Extrusion Machine—an engineering marvel designed to transform your production lines and boost your business efficiency.

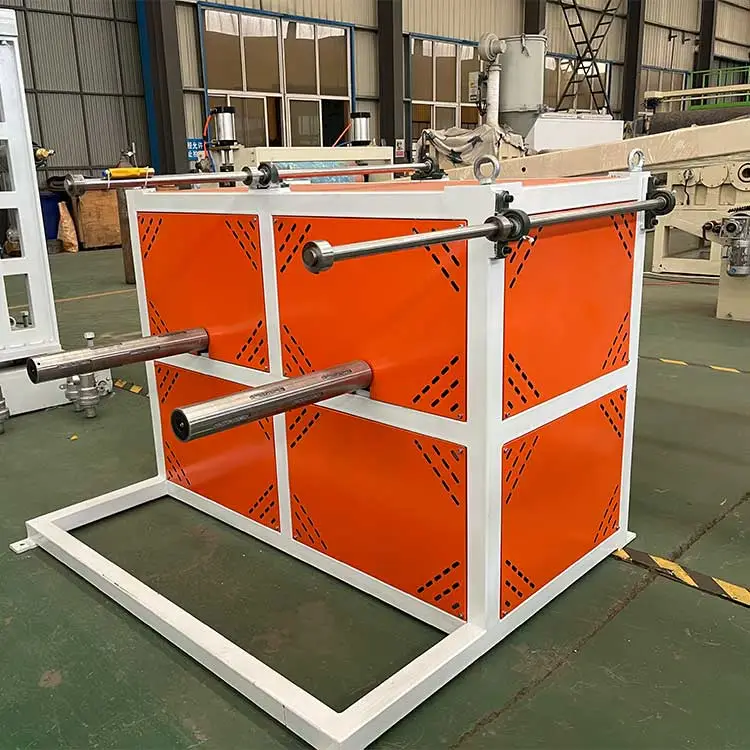

PVC Door Curtain Extrusion Machine Overview" class="product-image">

PVC Door Curtain Extrusion Machine Overview" class="product-image">

This machine is specifically crafted to manufacture high-quality PVC door curtains, widely used in commercial and industrial settings for temperature control, insect prevention, and energy conservation. With its advanced extrusion technology, it ensures consistent thickness, durability, and smooth operation, making it an indispensable tool for businesses aiming to enhance their product offerings.

Many manufacturers face issues like inconsistent output, high energy consumption, and frequent downtime. Our PVC Door Curtain Extrusion Machine tackles these head-on with optimized performance and efficiency.

| Parameter | Specification | Benefit |

|---|---|---|

| Extrusion Output | Up to 150 kg/h | High production capacity for meeting large orders |

| Motor Power | 15 kW | Energy-efficient operation reduces electricity costs |

| Screw Diameter | 65 mm | Ensures uniform melting and extrusion for quality products |

| Heating Zones | 4 zones with precise temperature control | Prevents material degradation and ensures consistency |

| Machine Dimensions | 3000 x 1200 x 1800 mm | Space-saving design ideal for compact workshops |

This PVC Door Curtain Extrusion Machine is perfect for a wide range of users, from small-scale entrepreneurs to large manufacturing plants. It caters to:

Common scenarios include warehouses, food processing units, and retail stores where maintaining indoor temperatures and hygiene is crucial. With this machine, users can produce custom-sized curtains tailored to specific doorways, enhancing functionality and aesthetics.

Imagine the satisfaction of seeing your production line run seamlessly, with minimal waste and maximum output. Users of the PVC Door Curtain Extrusion Machine report a significant reduction in operational headaches—no more uneven strips or frequent breakdowns. Instead, they enjoy smoother workflows, faster turnaround times, and the confidence that comes from delivering superior products to their clients. This machine doesn't just solve problems; it empowers businesses to grow sustainably, fostering a sense of pride and accomplishment.

While many extrusion machines are available, Qingdao Eaststar Plastic Machinery Co., Ltd.'s PVC Door Curtain Extrusion Machine offers unique advantages:

What types of PVC materials can this machine process?

The machine is compatible with a wide range of PVC compounds, including rigid and flexible types. It can handle additives for UV resistance, colorants, and other modifiers to meet specific product requirements. For optimal results, we recommend using high-quality PVC resins with consistent particle size.

How easy is it to set up and operate the extrusion machine?

Designed for user-friendliness, the machine comes with a detailed manual and optional training sessions. The PLC interface allows for easy parameter adjustments, and most users can start production within a day of installation. Regular maintenance is straightforward, with accessible parts and clear guidelines.

What is the typical maintenance schedule for this equipment?

We recommend routine checks every 500 operating hours, including cleaning the screw and barrel, inspecting heaters, and lubricating moving parts. The machine is built for low maintenance, but following this schedule helps prevent unexpected downtime and extends its lifespan. Spare parts are readily available through our global network.

Can the machine produce door curtains of different sizes and thicknesses?

Yes, it offers adjustable settings for width, thickness, and length. By modifying the die and extrusion speed, you can create curtains ranging from thin, lightweight strips to thicker, heavy-duty versions. This versatility makes it ideal for diverse applications, from residential to industrial use.

What kind of after-sales support does Qingdao Eaststar provide?

We offer comprehensive support, including a one-year warranty, online troubleshooting, and access to technical experts. Our team is available for remote assistance or on-site visits if needed, ensuring that your investment is protected and your production remains efficient.

How does this machine contribute to energy savings?

With its efficient motor and precise temperature control, the machine reduces power consumption by up to 20% compared to conventional models. The optimized heating zones ensure that energy is used only where needed, lowering operational costs and supporting sustainable practices.