PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

When it comes to manufacturing superior PVC electrostatic boards used in applications like cleanroom partitions, advertising displays, and electronic component housing, efficiency and precision are non-negotiable. The PVC Electrostatic Board Extruder Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a pinnacle of innovation, designed to transform raw PVC materials into flawless, high-performance electrostatic sheets with remarkable consistency. This machine is not just a piece of equipment; it's a strategic investment that elevates production lines, reduces operational costs, and ensures your products meet the highest industry standards. By integrating cutting-edge extrusion technology, robust construction, and user-friendly controls, it delivers boards with excellent surface finish, uniform thickness, and superior electrostatic dissipation properties. Whether you're scaling up operations or entering new markets, this extruder empowers you to produce boards that resist dust accumulation, enhance safety, and impress end-users with their durability and clarity. Imagine a production floor where downtime is minimized, waste is drastically reduced, and every sheet produced exudes quality – that's the reality with Eaststar's expertly engineered solution.

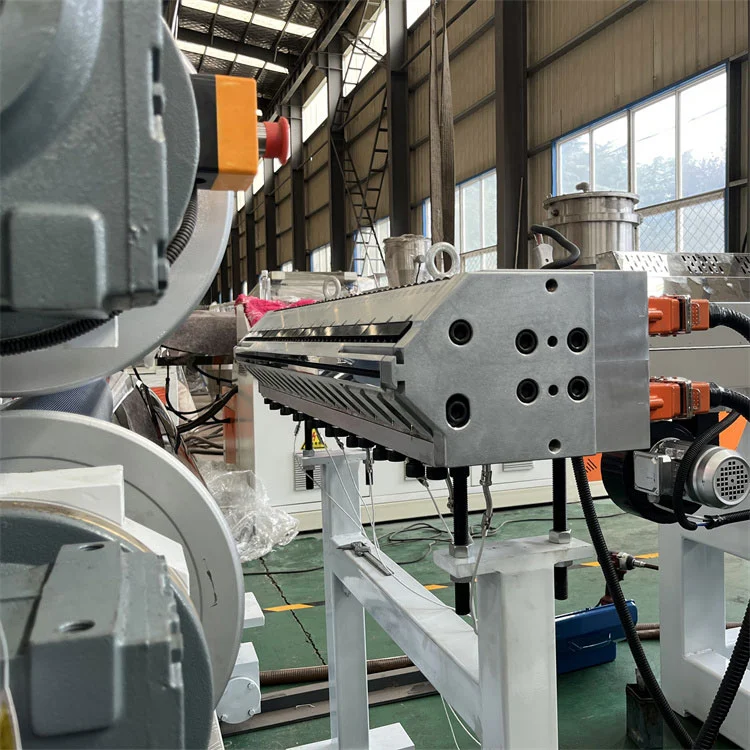

At the heart of this machine lies a commitment to excellence, driven by features that set it apart. The extruder employs a high-torque, energy-efficient screw design that ensures optimal melting and mixing of PVC compounds, resulting in boards with minimal internal stresses and exceptional dimensional stability. Coupled with a precision temperature control system, it maintains consistent heat profiles, preventing defects like warping or bubbles. The die head is custom-engineered for electrostatic board production, allowing for adjustable thickness and width to meet diverse client specifications. Additionally, the incorporation of advanced electrostatic treatment units within the line ensures that each board achieves the desired surface resistance, crucial for applications in sensitive environments. Built from hardened alloys and corrosion-resistant materials, the machine promises longevity even under continuous operation. Qingdao Eaststar Plastic Machinery Co., Ltd. backs this with rigorous quality checks and comprehensive after-sales support, including installation guidance and maintenance training, so you can focus on growing your business with confidence.

Many manufacturers face challenges such as inconsistent board quality, high energy consumption, and frequent maintenance halts. Our PVC Electrostatic Board Extruder Machine addresses these directly through innovative engineering. For instance, the integrated PLC system automates adjustments based on real-time feedback, reducing human error and enhancing repeatability. The modular design allows for easy upgrades or customization, adapting to evolving market demands. Below is a summary of key parameters that highlight its capabilities:

| Parameter | Specification |

|---|---|

| Output Capacity | 200-500 kg/h (adjustable based on material and thickness) |

| Screw Diameter | 65-120 mm (variants available) |

| Power Consumption | Optimized to reduce energy use by up to 20% compared to conventional models |

| Board Thickness Range | 1-10 mm (customizable) |

| Electrostatic Properties | Surface resistance 10^6-10^9 Ω/sq, ensuring effective static dissipation |

| Cooling System | Multi-stage cooling for uniform solidification |

This extruder is ideal for businesses in the construction, electronics, and advertising industries. For example, cleanroom equipment suppliers can rely on it to produce partitions that maintain sterile conditions by repelling dust. Electronics manufacturers use the boards for housing sensitive components, preventing static damage. In retail, it enables the creation of vibrant, long-lasting signage. Users often report a sense of relief and pride as they overcome production bottlenecks, achieve faster turnaround times, and receive positive feedback from clients. By eliminating common issues like surface imperfections or static buildup, it solves the frustration of reworks and returns, fostering trust in your brand. The machine's quiet operation and low emission design also contribute to a safer, more pleasant workplace, boosting team morale.

What makes this product truly stand out is its holistic approach to extrusion. Unlike many competitors, Qingdao Eaststar Plastic Machinery Co., Ltd. incorporates real-time monitoring sensors that predict maintenance needs, slashing unexpected downtime. The machine's compatibility with recycled PVC materials supports sustainability goals without compromising quality. Furthermore, the customer-centric design includes touch-screen interfaces with multilingual support, making it accessible for operators worldwide. These features, combined with competitive pricing and global service networks, position it as a leader in the market.

What is the typical lead time for delivery and installation?

Delivery usually takes 4-6 weeks after order confirmation, depending on customization. Installation is completed within 1-2 weeks by our trained technicians, who also provide on-site training for your team.

Can the machine handle different colors or additives in PVC?

Yes, the extruder is designed for versatility. It can process PVC with various colorants, UV stabilizers, or anti-static additives. The screw and barrel are engineered to ensure uniform dispersion, maintaining consistent quality across batches.

How does the electrostatic treatment work in the production line?

The treatment unit applies a controlled corona discharge or chemical coating during extrusion, modifying the surface energy to achieve the desired electrostatic properties. This integrated process eliminates the need for post-treatment, saving time and resources.

What kind of maintenance is required, and how often?

Routine maintenance includes screw and barrel inspection every 500 hours of operation, with lubrication every 200 hours. The PLC system alerts operators to schedule maintenance, preventing major breakdowns. Spare parts are readily available through our global network.

Is technical support available after purchase?

Absolutely. Qingdao Eaststar Plastic Machinery Co., Ltd. offers 24/7 remote support and has service centers in multiple regions. We also provide online resources, including video tutorials and manuals, to assist with troubleshooting.

Can the machine be customized for specific production needs?

Yes, we offer customization options for output speed, board dimensions, and additional features like automated cutting or stacking. Our engineering team works closely with clients to tailor the machine to their unique requirements.

What safety features are included?

Safety is a priority. The machine comes with emergency stop buttons, overload protection, and insulated electrical components. It complies with international standards such as CE and ISO, ensuring safe operation in various environments.