PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

In the rapidly evolving world of industrial manufacturing, efficiency, durability, and precision are not just desirable—they are essential. At Qingdao Eaststar Plastic Machinery Co., Ltd., we understand these demands intimately. Our cutting-edge PVDF Sheet Extruder Machine stands as a testament to our commitment to excellence, designed to meet the rigorous needs of modern production lines. Whether you're in chemical processing, construction, or high-tech electronics, this machine redefines what's possible in polymer extrusion.

Imagine a machine that not only produces high-quality PVDF sheets but does so with remarkable consistency and speed. That's the core of our PVDF Sheet Extruder Machine. Engineered with state-of-the-art technology, it transforms raw PVDF (polyvinylidene fluoride) materials into uniform sheets ideal for applications requiring exceptional chemical resistance, thermal stability, and mechanical strength. From industrial linings to specialty components, this machine ensures your products meet the highest standards without compromise.

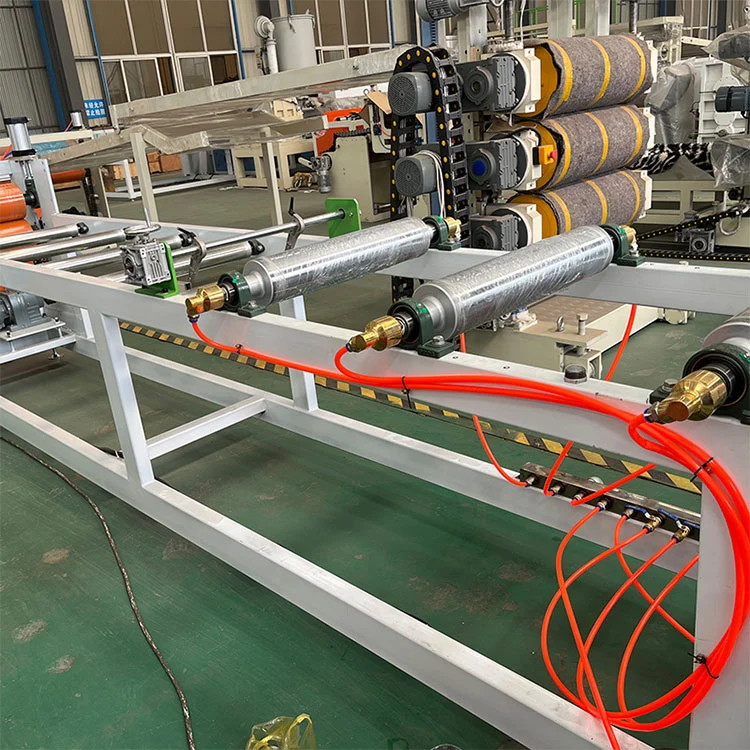

What truly sets our PVDF Sheet Extruder Machine apart is its innovative design and robust performance. Featuring an advanced screw and barrel system, it minimizes material degradation while maximizing output. The integrated temperature control system ensures precise heating and cooling, reducing energy consumption and waste. With easy-to-use interfaces and automated features, operators can achieve optimal results with minimal training, boosting productivity across your facility.

Let's delve into the specifics. Many industries face challenges like inconsistent sheet thickness or high maintenance costs. Our machine addresses these directly with its precision engineering. For instance, the dual-stage extrusion process ensures uniform material distribution, while corrosion-resistant components extend the machine's lifespan even in harsh environments. Below is a table highlighting key parameters:

| Parameter | Specification |

|---|---|

| Output Capacity | Up to 500 kg/h, depending on material and settings |

| Screw Diameter | Options from 60mm to 120mm for varied production needs |

| Heating Zones | 5-8 zones with ±1°C accuracy for optimal melt control |

| Power Consumption | Energy-efficient design, reducing operational costs by up to 20% |

| Sheet Thickness Range | 0.5mm to 10mm, adjustable with high precision |

This machine is tailored for professionals in sectors like chemical engineering, where PVDF sheets serve as liners for tanks and pipes, or in architecture for durable cladding. It's also ideal for electronics manufacturers needing insulating components. By streamlining production, it empowers businesses to scale operations, reduce downtime, and deliver superior products that withstand extreme conditions.

Users often share how this machine transforms their workflow. One client in the water treatment industry reported a 30% increase in output efficiency, thanks to the consistent sheet quality and reduced material waste. Another in aerospace highlighted the machine's reliability, noting how it handles high-performance PVDF blends without faltering. This isn't just about machinery; it's about enabling innovation and peace of mind, knowing that every sheet produced meets exacting standards.

Compared to standard extruders, our PVDF Sheet Extruder Machine boasts unique features like a modular design for easy upgrades and maintenance. The integration of IoT capabilities allows for real-time monitoring and predictive maintenance, minimizing unexpected breakdowns. Plus, with Qingdao Eaststar's global support network, you gain access to expert assistance and spare parts, ensuring long-term performance.

We understand that investing in new equipment comes with questions. Here are some common queries answered in detail:

What is the typical lifespan of this extruder machine?

With proper maintenance, the PVDF Sheet Extruder Machine can operate efficiently for over 10 years. Key components are made from high-grade materials to resist wear, and regular servicing recommendations are provided to extend longevity.

How does it handle different PVDF grades?

The machine is versatile, accommodating various PVDF resins including homopolymers and copolymers. Adjustable screw speeds and temperature settings allow customization for specific material properties, ensuring optimal extrusion regardless of grade.

Is training provided for operators?

Yes, Qingdao Eaststar offers comprehensive training sessions, both on-site and online. We cover operation, troubleshooting, and safety protocols to ensure your team can maximize the machine's potential from day one.

Can it integrate with existing production lines?

Absolutely. The machine is designed with compatibility in mind, featuring standard interfaces and modular connections. Our engineers can assist with integration plans to minimize disruption during installation.

What safety features are included?

Safety is a priority, with features like emergency stop buttons, overload protection, and insulated heating elements. All systems comply with international safety standards to protect operators and equipment.

How energy-efficient is it compared to older models?

This model incorporates advanced energy-saving technologies, such as regenerative drives and optimized heating cycles. Users often see a 15-25% reduction in energy costs compared to conventional extruders, making it an eco-friendly choice.

From its robust construction to its user-centric design, the PVDF Sheet Extruder Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. is more than a tool—it's a partner in progress. Embrace the future of manufacturing with a solution that delivers reliability, efficiency, and unmatched quality.