PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

In the world of civil engineering and construction, effective drainage solutions are not just a luxury—they are a necessity. At Qingdao Eaststar Plastic Machinery Co., Ltd., we pride ourselves on delivering cutting-edge machinery that transforms how industries manage water drainage. The HDPE Drainage Board Extruder Machine stands as a testament to our commitment to innovation, quality, and customer satisfaction. This advanced equipment is meticulously engineered to produce high-density polyethylene (HDPE) drainage boards, which are essential for applications in landscaping, foundation protection, tunnel construction, and more. By automating the production process, it ensures consistent, high-performance output that meets the rigorous demands of modern infrastructure projects.

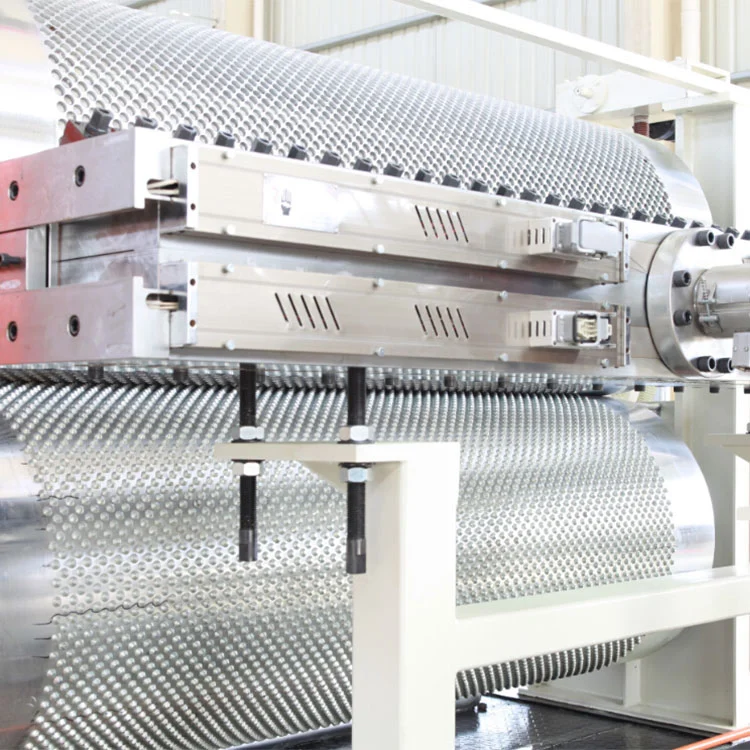

Imagine a machine that not only streamlines your manufacturing workflow but also enhances the durability and efficiency of your drainage systems. The HDPE Drainage Board Extruder Machine does exactly that. It leverages state-of-the-art extrusion technology to create boards with superior strength, flexibility, and resistance to environmental stressors. Whether you're working on a large-scale commercial development or a residential project, this machine empowers you to produce drainage solutions that last for decades, reducing maintenance costs and improving overall project integrity.

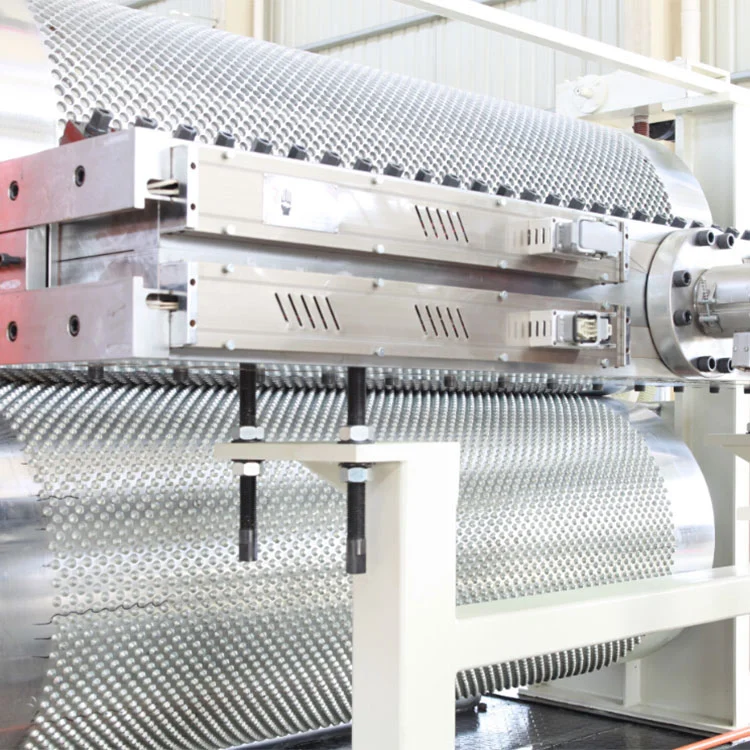

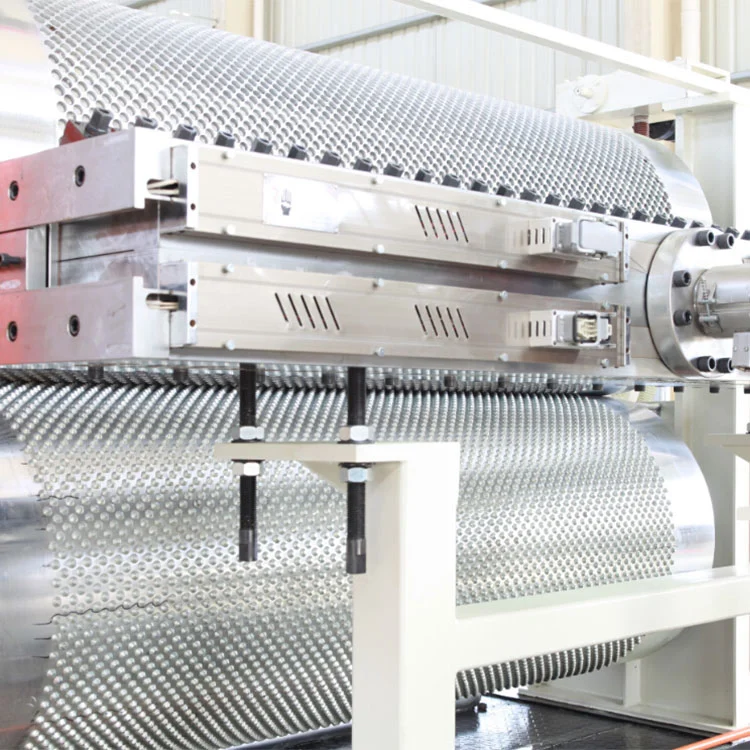

What makes the HDPE Drainage Board Extruder Machine a standout choice? It begins with its robust construction and intelligent design. Crafted from premium materials, the machine ensures longevity and minimal downtime. Its precision extrusion system allows for customizable board thickness and patterns, catering to diverse project requirements. Moreover, it incorporates energy-efficient mechanisms that lower operational costs while maintaining high output rates. With user-friendly controls and automated features, operators can achieve optimal results with minimal training, boosting productivity and reducing human error.

Beyond technical specs, the machine delivers tangible benefits in real-world scenarios. For instance, in areas prone to soil erosion or waterlogging, the HDPE boards produced act as reliable barriers, facilitating efficient water flow and preventing structural damage. This translates to safer environments and long-term cost savings for property owners and developers alike.

To help you understand the capabilities of the HDPE Drainage Board Extruder Machine, we've outlined key parameters based on common industry challenges. For example, many projects struggle with inconsistent board quality or slow production speeds. Our machine addresses these issues head-on with advanced calibration and cooling systems that ensure uniform thickness and rapid output.

| Parameter | Specification |

|---|---|

| Production Capacity | Up to 500 kg/h |

| Board Thickness Range | 10-50 mm |

| Power Consumption | Approx. 150-200 kW |

| Extrusion Screw Diameter | 90-120 mm |

| Control System | PLC-based with touchscreen interface |

These specs highlight how the machine combats inefficiencies, such as material waste or delayed timelines, by offering reliable performance and adaptability. Whether you need boards for geotechnical applications or urban drainage networks, this equipment provides a scalable solution that grows with your business.

The HDPE Drainage Board Extruder Machine is ideal for a wide range of professionals and industries. Construction companies, civil engineers, and landscape architects will find it invaluable for creating effective drainage systems in projects like highways, sports fields, and building foundations. Municipalities and environmental agencies can use it to develop sustainable water management solutions for public spaces. Even recycling facilities and material suppliers can integrate it into their operations to produce eco-friendly drainage products from recycled HDPE, aligning with green initiatives.

Common usage scenarios include installing drainage boards in basements to prevent moisture buildup, along road embankments to control runoff, or in agricultural settings to enhance soil aeration. By investing in this machine, users gain a competitive edge, enabling them to tackle complex projects with confidence and efficiency.

Using the HDPE Drainage Board Extruder Machine goes beyond mere functionality—it instills a sense of reliability and peace of mind. Picture a project manager who no longer worries about drainage failures causing costly delays or safety hazards. With this machine, they experience a seamless production process that delivers consistent, high-quality boards. This reliability fosters trust among clients and stakeholders, enhancing reputations and opening doors to new business opportunities. For engineers, it means focusing on creative design rather than troubleshooting equipment issues, leading to more innovative and sustainable solutions.

The machine also addresses environmental concerns by supporting the use of HDPE, a recyclable material that reduces plastic waste. Users often report a feeling of contribution to eco-friendly practices, knowing their projects promote long-term sustainability. This emotional connection strengthens brand loyalty and motivates continued investment in advanced technology.

In a crowded marketplace, the HDPE Drainage Board Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. distinguishes itself through several key differentiators. Firstly, its modular design allows for easy customization and upgrades, adapting to evolving industry standards. Unlike many competitors, it features integrated quality monitoring systems that detect imperfections in real-time, ensuring every board meets strict benchmarks. Additionally, the machine's low maintenance requirements and comprehensive after-sales support—including training and spare parts availability—reduce long-term ownership costs.

Another standout aspect is its compatibility with various raw materials, including virgin and recycled HDPE, giving users flexibility in sourcing and cost management. By combining durability, efficiency, and adaptability, this machine not only matches but exceeds the expectations of modern manufacturing environments.

What is the typical lifespan of the HDPE Drainage Board Extruder Machine?

With proper maintenance, the machine can operate efficiently for over 10 years. Regular servicing and using genuine parts from Qingdao Eaststar Plastic Machinery Co., Ltd. help maximize its longevity and performance.

Can the machine handle recycled HDPE materials?

Yes, it is designed to process both virgin and recycled HDPE, providing flexibility in material choice. The extrusion system includes filters and melt pumps to ensure consistent quality, even with varying material grades.

How easy is it to train operators on this machine?

The intuitive PLC-based control system with a touchscreen interface makes training straightforward. Most operators become proficient within a few days, and we offer comprehensive manuals and online support to facilitate the learning process.

What kind of after-sales service do you provide?

We offer 24/7 technical support, on-site installation assistance, and a warranty covering critical components. Our team is dedicated to ensuring smooth operation and addressing any issues promptly to minimize downtime.

Are there customization options for different board designs?

Absolutely. The machine allows adjustments in thickness, width, and surface patterns through modular dies and calibration units. This versatility enables production of boards tailored to specific project needs, from standard drainage layers to specialized geotechnical applications.

What safety features are included?

Safety is a top priority. The machine comes with emergency stop buttons, overload protection, and insulated electrical components. Regular safety audits and compliance with international standards ensure a secure working environment.