PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

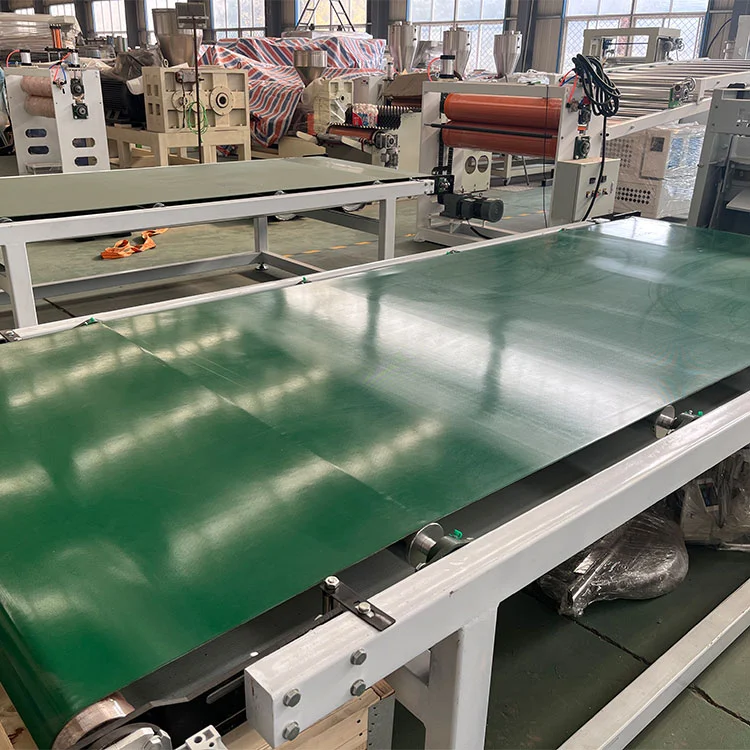

In the world of industrial manufacturing, efficiency and innovation are paramount. The PE PP Double-layer Co-extrusion Board Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a testament to cutting-edge engineering, designed to revolutionize the production of durable, versatile plastic boards. This advanced machinery seamlessly combines polyethylene (PE) and polypropylene (PP) layers through co-extrusion technology, resulting in boards that offer superior strength, flexibility, and resistance to environmental factors. Whether for packaging, construction, or automotive applications, this machine delivers consistent, high-quality output that meets the rigorous demands of modern industries. By integrating smart automation and precision control, it empowers businesses to scale their operations while maintaining unparalleled product integrity.

What sets this machine apart is its holistic approach to performance and reliability. Crafted with premium materials and state-of-the-art components, it ensures minimal downtime and extended service life. The intuitive interface allows operators to monitor and adjust parameters in real-time, reducing the learning curve and enhancing productivity. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs each unit with rigorous quality checks and comprehensive support, giving customers the confidence to invest in a solution that grows with their needs. From small-scale workshops to large factories, this machine adapts effortlessly, making it a cornerstone for businesses aiming to lead in their respective markets.

Imagine a scenario where production delays and material waste are common hurdles. The PE PP Double-layer Co-extrusion Board Machine addresses this head-on with its optimized extrusion system, which precisely controls layer thickness and adhesion. This results in boards that are not only robust but also lightweight, reducing shipping costs and environmental impact. For instance, in the packaging industry, these boards provide exceptional barrier properties, protecting goods from moisture and UV radiation. In construction, they serve as reliable insulating materials that withstand harsh weather conditions. By leveraging this technology, users experience a significant boost in output quality and a reduction in operational expenses, transforming challenges into opportunities for growth.

To help you make an informed decision, here are some essential parameters based on common industry needs. These details highlight how the machine tackles specific pain points, such as inconsistent board thickness or high energy consumption, by offering tailored solutions.

| Parameter | Specification | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/hour | Enables high-volume production without compromising speed |

| Layer Thickness Control | Adjustable from 0.5 mm to 10 mm | Ensures precision for custom applications, reducing material waste |

| Power Consumption | Optimized for energy efficiency, with savings up to 20% | Lowers operational costs and supports sustainable practices |

| Automation Level | Fully automated with PLC system | Minimizes manual intervention, enhancing safety and consistency |

This machine is ideal for a wide range of users, from startups seeking to establish a foothold in the plastic manufacturing sector to established corporations looking to upgrade their production lines. It excels in environments such as industrial plants, recycling facilities, and custom fabrication shops. For example, a business specializing in eco-friendly packaging can utilize the co-extrusion process to create biodegradable boards that appeal to environmentally conscious consumers. Similarly, automotive parts manufacturers can produce lightweight, impact-resistant components that enhance vehicle performance. By catering to diverse needs, the PE PP Double-layer Co-extrusion Board Machine becomes an indispensable asset for anyone committed to quality and innovation.

Using this machine often leads to a profound sense of accomplishment and relief. Picture a factory manager who previously struggled with frequent machine breakdowns and subpar outputs. After integrating the PE PP Double-layer Co-extrusion Board Machine, they witness smoother operations, happier clients, and a notable increase in profitability. The emotional payoff includes reduced stress, renewed confidence in product delivery, and the pride of offering superior goods that stand out in competitive markets. It solves core issues like inconsistent quality and high maintenance costs, allowing users to focus on strategic growth rather than daily troubleshooting.

Compared to standard extrusion machines, this model from Qingdao Eaststar Plastic Machinery Co., Ltd. incorporates several unique elements. The dual-layer co-extrusion technology allows for customized material combinations, enabling users to tailor boards for specific strength, flexibility, or aesthetic requirements. Additionally, its modular design facilitates easy upgrades and maintenance, future-proofing your investment. Unlike competitors, it includes integrated cooling systems that prevent warping and ensure uniform board surfaces. These highlights, combined with a user-centric approach, make it a preferred choice for those who value long-term reliability and adaptability.

What materials can the machine process besides PE and PP?

The machine is primarily optimized for PE and PP but can handle other compatible polymers with minor adjustments. This flexibility allows for experimentation with materials like ABS or HDPE, depending on your production goals. Always consult with our technical team for specific material compatibility to ensure optimal performance.

How does the co-extrusion process enhance board quality?

Co-extrusion bonds two distinct layers into a single board, combining the best properties of each material. For instance, one layer might provide rigidity while the other offers impact resistance. This results in a product that outperforms single-layer boards in durability, barrier protection, and overall lifespan, making it suitable for demanding applications.

Is training provided for operating the machine?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers comprehensive training sessions during installation. These cover everything from basic operations to troubleshooting, ensuring your team can maximize the machine's potential. Ongoing support is available via remote assistance or on-site visits if needed.

What maintenance routines are recommended?

Regular maintenance includes cleaning extrusion heads, lubricating moving parts, and checking electronic components. We provide a detailed schedule in the user manual, typically suggesting monthly inspections for high-use environments. This proactive approach minimizes downtime and extends the machine's longevity.

Can the machine be customized for specific output sizes?

Absolutely. The machine features adjustable dies and settings that allow for custom board widths, thicknesses, and lengths. Whether you need standard sizes or bespoke dimensions, our engineers can help configure the system to meet your exact requirements without compromising efficiency.