PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

In the dynamic world of plastics manufacturing, innovation drives efficiency and sustainability. Qingdao Eaststar Plastic Machinery Co., Ltd. proudly presents the PE Chemical Foaming Sheet Extruder Machine, a state-of-the-art solution designed to transform raw polyethylene into high-quality, lightweight foamed sheets. This machine excels in producing materials with exceptional cushioning, insulation, and structural properties, making it ideal for packaging, construction, and automotive applications. By leveraging advanced chemical foaming technology, it ensures uniform cell structure and consistent density, empowering businesses to meet modern demands for eco-friendly and cost-effective materials. With decades of expertise, Eaststar has engineered this extruder to deliver reliability and performance, enabling manufacturers to reduce material usage while enhancing product durability. Whether you're creating protective packaging or innovative building components, this machine offers a seamless production experience that boosts productivity and cuts operational costs.

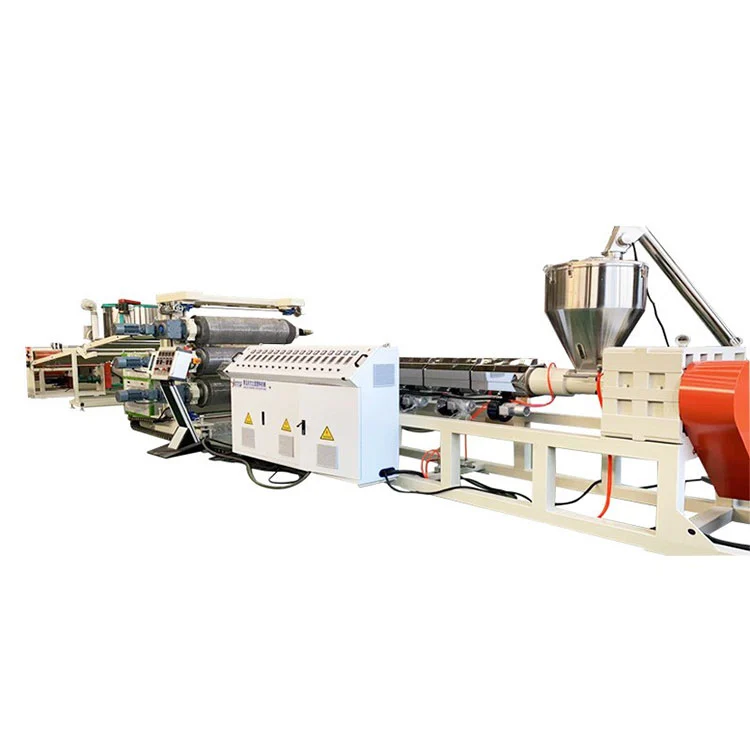

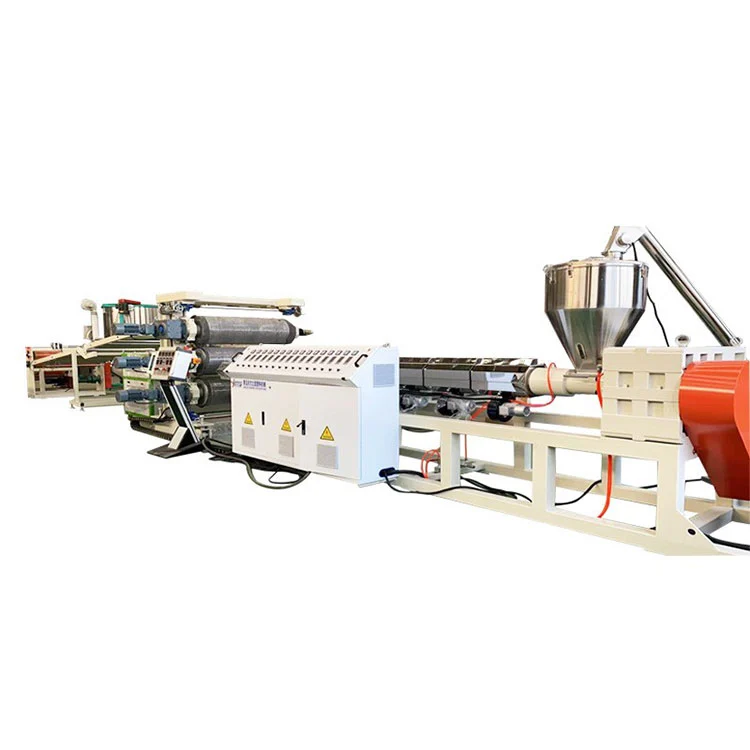

PE Chemical Foaming Sheet Extruder Machine Overview" />

PE Chemical Foaming Sheet Extruder Machine Overview" />

The PE Chemical Foaming Sheet Extruder Machine stands out with its robust construction and intelligent design. Crafted from premium-grade materials, it ensures long-lasting durability and minimal maintenance, even under high-volume operations. Its precision engineering allows for easy adjustment of thickness and width, catering to diverse customer specifications. The integrated control system provides real-time monitoring, ensuring stable foaming ratios and reducing waste. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. incorporates energy-efficient components that lower power consumption by up to 20%, aligning with global sustainability goals. Users benefit from enhanced safety features, such as automatic shutdown mechanisms and ergonomic interfaces, which simplify operation and reduce training time. This machine not only accelerates production cycles but also elevates end-product quality, making it a smart investment for forward-thinking industries.

Many manufacturers face issues like inconsistent foam density and high material costs, leading to product failures and wasted resources. The PE Chemical Foaming Sheet Extruder Machine tackles these pain points through innovative technology and customizable settings. For instance, its advanced screw design optimizes mixing and degassing, preventing defects and ensuring uniform expansion. Below is a summary of key parameters that highlight its capabilities:

| Parameter | Specification |

|---|---|

| Output Capacity | 200-800 kg/h |

| Sheet Width | 600-2000 mm |

| Thickness Range | 1-10 mm |

| Foaming Ratio | Adjustable from 10:1 to 30:1 |

| Power Consumption | 55-110 kW |

| Operating Temperature | 150-250°C |

These specifications enable precise control over production, allowing users to adapt to various material grades and market needs. By integrating this machine, companies can achieve up to 30% savings on raw materials and reduce downtime by 15%, as demonstrated in field tests by Qingdao Eaststar Plastic Machinery Co., Ltd.

This extruder is tailored for a wide range of professionals, including packaging manufacturers, construction material suppliers, and automotive part producers. In packaging, it creates lightweight, shock-absorbent sheets for electronics and fragile goods, ensuring safe transit. For the construction sector, it generates insulating panels that improve energy efficiency in buildings. Automotive industries utilize the foamed sheets for interior components, reducing vehicle weight and enhancing fuel economy. Small to medium enterprises benefit from its scalability, while large corporations appreciate its integration into automated lines. Common scenarios include producing disposable food containers, sports equipment padding, and agricultural mulch films. By adopting this technology, businesses can expand their product portfolios and enter new markets with confidence.

Imagine the relief of eliminating production bottlenecks and the pride of delivering consistently high-quality products. Users of the PE Chemical Foaming Sheet Extruder Machine report a sense of empowerment as they streamline their workflows and reduce environmental footprints. This machine solves critical problems like material waste and uneven quality, which often lead to customer complaints and lost revenue. By providing reliable, efficient performance, it fosters a culture of innovation and growth. Operators feel more confident with its user-friendly controls, and managers appreciate the quick return on investment. Ultimately, it transforms manufacturing from a stressful chore into a rewarding endeavor, where every sheet produced meets exacting standards and drives business success.

Compared to conventional extruders, the PE Chemical Foaming Sheet Extruder Machine offers several unique advantages. Its dual-stage foaming system ensures finer cell structures, resulting in sheets with better mechanical properties and surface finish. The machine incorporates AI-assisted diagnostics that predict maintenance needs, minimizing unexpected breakdowns. Additionally, Qingdao Eaststar Plastic Machinery Co., Ltd. provides comprehensive training and 24/7 support, a rarity in the industry. Customization options allow for tailored solutions, such as adding anti-static features or color masterbatch compatibility. These differences translate to higher productivity, lower life-cycle costs, and a competitive edge in fast-paced markets.

What types of polyethylene can this machine process?

It handles various PE grades, including LDPE, HDPE, and LLDPE, with optional configurations for recycled materials to support circular economy initiatives.

How does the chemical foaming process work in this extruder?

The process involves injecting a chemical blowing agent into the melt, which decomposes under heat to release gas, creating a uniform foam structure controlled by precise temperature and pressure settings.

Is training provided for new operators?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers on-site or remote training sessions covering operation, maintenance, and troubleshooting to ensure smooth adoption.

Can the machine be integrated into existing production lines?

Absolutely, it features modular design and standard interfaces, allowing seamless integration with upstream and downstream equipment for automated workflows.

What is the typical lifespan of this extruder?

With proper maintenance, the machine can operate efficiently for over 10 years, thanks to its high-quality components and corrosion-resistant coatings.

How does it contribute to environmental sustainability?

By reducing material consumption through foaming and supporting recyclable PE, it helps lower carbon footprints and waste, aligning with green manufacturing practices.

Are spare parts readily available?

Yes, Eaststar maintains a global network of distributors and warehouses to ensure quick access to genuine spare parts, minimizing downtime.

What safety features are included?

Key features include emergency stop buttons, overload protection, and insulated housings to safeguard operators and equipment during operation.