PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

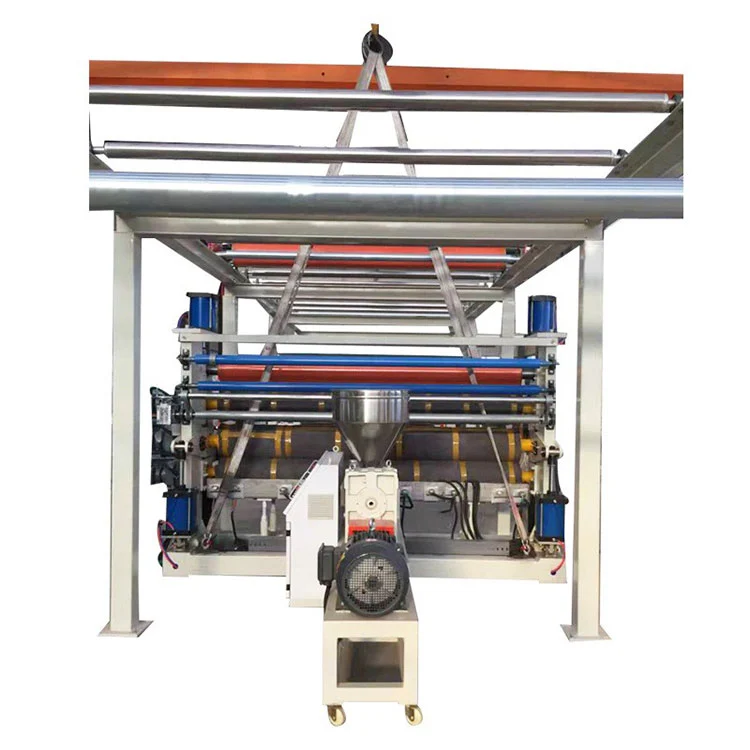

Welcome to the world of advanced automotive manufacturing with the TPE Car Mat Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. Designed for precision and efficiency, this machine transforms raw TPE (Thermoplastic Elastomer) materials into high-quality car mat sheets that meet the demanding standards of today's automotive industry. Whether you're producing mats for luxury vehicles or everyday cars, this extruder ensures consistent output, durability, and eco-friendliness. TPE is a popular choice due to its flexibility, resistance to wear, and recyclability, making it ideal for car mats that need to withstand heavy use and harsh weather conditions. With this machine, manufacturers can create products that not only protect vehicle interiors but also enhance the overall driving experience.

At the heart of the TPE Car Mat Sheet Extruder Machine lies cutting-edge technology that sets it apart. One of the standout features is its energy-efficient design, which reduces power consumption by up to 20% compared to conventional models. This not only lowers operational costs but also aligns with global sustainability goals. The machine incorporates a state-of-the-art screw and barrel system, crafted from high-grade alloy steel, ensuring minimal wear and tear over time. This translates to less downtime for maintenance and a longer lifespan, providing excellent return on investment. Additionally, the extrusion process is fully automated, with intuitive controls that allow operators to adjust parameters like temperature, speed, and thickness with ease. Imagine producing car mat sheets that are uniformly thick, free of defects, and ready for immediate use—this machine makes it possible. Plus, it supports a wide range of TPE materials, including recycled variants, empowering businesses to adopt greener practices without compromising on quality.

In the competitive automotive accessories market, many manufacturers struggle with inconsistent product quality and high production costs. For instance, uneven thickness in car mats can lead to poor fit and reduced durability, causing customer dissatisfaction. The TPE Car Mat Sheet Extruder Machine addresses this by offering precise control over the extrusion process, ensuring every sheet meets exact specifications. Here’s a quick look at some key parameters that highlight its capabilities:

| Parameter | Specification | Benefit |

|---|---|---|

| Output Capacity | 200-500 kg/h | High efficiency for mass production |

| Screw Diameter | 90-120 mm | Optimal material mixing and extrusion |

| Heating Zones | 5-7 zones | Uniform temperature control for consistent quality |

| Power Consumption | 15-25 kW | Energy savings and lower operational costs |

| Material Compatibility | TPE, TPR, and recycled blends | Versatility in sourcing and sustainability |

This machine is perfect for automotive parts manufacturers, car mat producers, and recycling facilities looking to scale their operations. It thrives in environments where high-volume production is essential, such as factories supplying to major automotive brands or aftermarket accessory companies. Picture a busy production floor where this extruder seamlessly integrates into existing lines, churning out mats that are resistant to oil, water, and UV rays. Users often report a sense of pride in delivering products that exceed customer expectations, knowing they've invested in reliable equipment from Qingdao Eaststar Plastic Machinery Co., Ltd. The emotional reward comes from solving real-world problems—like reducing waste and enhancing product longevity—which builds trust and loyalty among end-users.

What truly distinguishes the TPE Car Mat Sheet Extruder Machine from competitors is its focus on innovation and user-centric design. Unlike older models that require frequent calibration, this machine features a self-diagnostic system that alerts operators to potential issues before they escalate. This proactive approach minimizes disruptions and maximizes productivity. Furthermore, it supports custom configurations, allowing businesses to tailor the extrusion process to specific mat designs or material blends. For example, if a client needs mats with anti-slip properties or unique color patterns, the machine can adapt without compromising efficiency. The integration of IoT capabilities for remote monitoring is another game-changer, enabling managers to oversee production from anywhere, ensuring quality control in real-time. This level of flexibility and foresight makes it a standout choice in a crowded market.

Frequently Asked Questions:

What types of TPE materials can this machine process?

The TPE Car Mat Sheet Extruder Machine is compatible with a wide range of TPE grades, including virgin and recycled materials. It handles blends with varying hardness levels, from soft and flexible to rigid formulations, ensuring versatility for different car mat applications. This flexibility allows manufacturers to source cost-effective or eco-friendly materials without sacrificing performance.

How does the machine ensure consistent sheet thickness?

Through its advanced control system, the machine maintains precise temperature and speed settings across multiple heating zones. This eliminates variations in extrusion, resulting in uniform thickness throughout the sheet. Regular calibration and automated feedback loops further enhance accuracy, reducing the risk of defects and rework.

What maintenance is required for long-term use?

Routine maintenance includes cleaning the screw and barrel after each production run, checking for wear on key components, and lubricating moving parts as needed. The machine's durable construction minimizes frequent repairs, and Qingdao Eaststar Plastic Machinery Co., Ltd. provides comprehensive support, including spare parts and technical guidance, to ensure optimal performance over years of operation.

Can it be integrated with other production equipment?

Yes, the extruder is designed for seamless integration with downstream systems like cutting, molding, and packaging machines. Its modular design allows for easy connectivity, enabling a fully automated production line that boosts overall efficiency and reduces labor costs.

What safety features are included?

Safety is a top priority, with features such as emergency stop buttons, overload protection, and insulated heating elements. These measures protect operators from accidents and prevent damage to the machine, ensuring a secure working environment in line with industry standards.

Beyond technical specs, the TPE Car Mat Sheet Extruder Machine empowers businesses to innovate and grow. By producing high-quality mats that resist fading, cracking, and odors, it helps brands build a reputation for reliability. Users often share stories of expanded market reach and increased customer satisfaction, knowing their products contribute to a cleaner, safer driving experience. Whether you're a startup or an established player, this machine offers the tools to stay ahead in a dynamic industry.

In summary, the TPE Car Mat Sheet Extruder Machine combines innovation, efficiency, and sustainability to meet the evolving needs of automotive manufacturing. With robust construction and smart features, it supports a wide array of applications, from custom car mats to mass-produced accessories. As part of Qingdao Eaststar Plastic Machinery Co., Ltd.'s commitment to excellence, this machine represents a reliable partnership for businesses aiming to elevate their production capabilities and make a positive impact.