PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

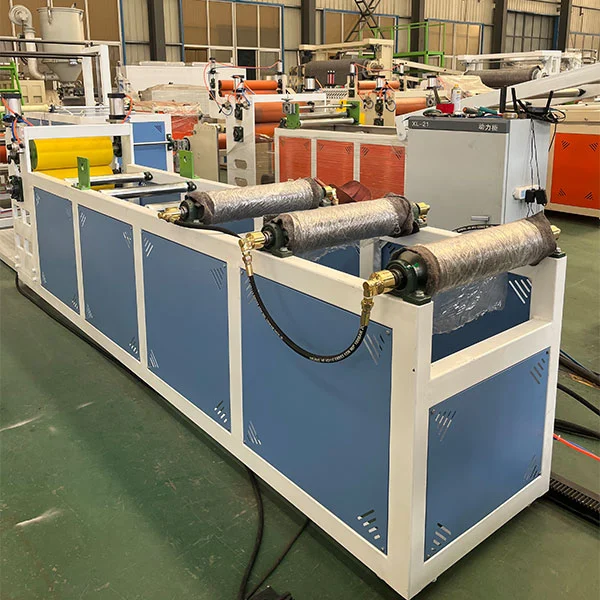

Step into a new world of efficiency and precision with the PA Nylon Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This state-of-the-art equipment is meticulously designed to produce high-quality nylon sheets that serve a wide range of industrial applications. From automotive components to consumer goods, our extruder machine ensures consistent output, making it an indispensable tool for manufacturers seeking reliability and superior performance.

At the core of this machine lies advanced extrusion technology, incorporating precision screw design and temperature control systems that guarantee uniform melting and shaping of polyamide materials. The result? Flawless nylon sheets with excellent mechanical properties, such as high tensile strength and resistance to abrasion. Whether you are producing gears, bearings, or insulation parts, this machine adapts seamlessly to various production demands, boosting your operational capabilities.

Imagine a production line where downtime is minimized, and output quality is consistently high. That’s the reality with our PA Nylon Sheet Extruder Machine. Its robust construction and intelligent automation reduce manual intervention, allowing your team to focus on innovation rather than troubleshooting. This not only enhances productivity but also empowers your business to meet tight deadlines without compromising on quality.

One of the standout features is its energy-efficient operation, which significantly cuts down on power consumption while maintaining top-tier performance. By integrating smart sensors and real-time monitoring, the machine optimizes resource use, contributing to both cost savings and environmental sustainability. For industries aiming to reduce their carbon footprint, this extruder is a game-changer.

Let’s delve into specific scenarios where this machine excels. Many manufacturers face challenges with material waste and inconsistent sheet thickness, leading to rejected batches and financial losses. Our extruder addresses these pain points through precise calibration and automated feedback systems. Below is a table showcasing key parameters that highlight its capabilities:

| Parameter | Value |

|---|---|

| Output Capacity | Up to 500 kg/h |

| Sheet Thickness Range | 0.5 mm to 10 mm |

| Power Consumption | Optimized for 15% less than standard models |

| Temperature Control Accuracy | ±1°C |

| Noise Level | < 75 dB |

This data underscores the machine’s ability to deliver precise, high-volume production while keeping operational costs in check. Engineers and production managers in sectors like packaging, electronics, and construction will find it particularly beneficial. For instance, in automotive manufacturing, the consistent quality of nylon sheets ensures durable parts that withstand rigorous use, enhancing vehicle safety and longevity.

Beyond technical specifications, the emotional impact is profound. Users often report a sense of confidence and relief, knowing their production lines are backed by reliable technology. Gone are the days of frequent breakdowns and quality fluctuations. Instead, businesses experience smoother operations, leading to increased customer satisfaction and brand reputation. This machine doesn’t just produce sheets; it builds trust.

What sets the PA Nylon Sheet Extruder Machine apart from competitors? Its integration of modular components allows for easy customization and upgrades, ensuring it grows with your business. Unlike many standard extruders, it features a user-friendly interface with touch-screen controls, making it accessible even for operators with minimal training. Additionally, Qingdao Eaststar Plastic Machinery Co., Ltd. provides comprehensive after-sales support, including remote diagnostics and spare parts availability, ensuring minimal disruption to your workflow.

For those curious about common queries, here are some frequently asked questions:

What materials can this extruder handle besides nylon?

The machine is primarily optimized for polyamide (nylon) materials, but it can also process other thermoplastics with minor adjustments. Consult our technical team for specific material compatibility.

How long does installation and setup take?

Typically, installation is completed within 2-3 days, including calibration and operator training. We offer on-site support to ensure a smooth transition.

What maintenance is required to keep the machine running efficiently?

Routine maintenance includes cleaning the screw and barrel, checking electrical components, and lubricating moving parts. We provide a detailed maintenance schedule and remote monitoring to prevent issues.

Can the extruder be integrated into existing production lines?

Yes, it is designed for seamless integration with conveyor systems and downstream equipment. Our engineers can assist with customization to fit your setup.

Is technical support available internationally?

Absolutely. Qingdao Eaststar Plastic Machinery Co., Ltd. has a global network of service centers, offering 24/7 support and rapid response times.

In summary, the PA Nylon Sheet Extruder Machine embodies innovation and reliability, tailored for modern industrial needs. Its combination of precision engineering, energy efficiency, and user-centric design makes it a valuable asset for any manufacturing facility. By choosing this machine, you are not only investing in equipment but also in the future of your production capabilities.