PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

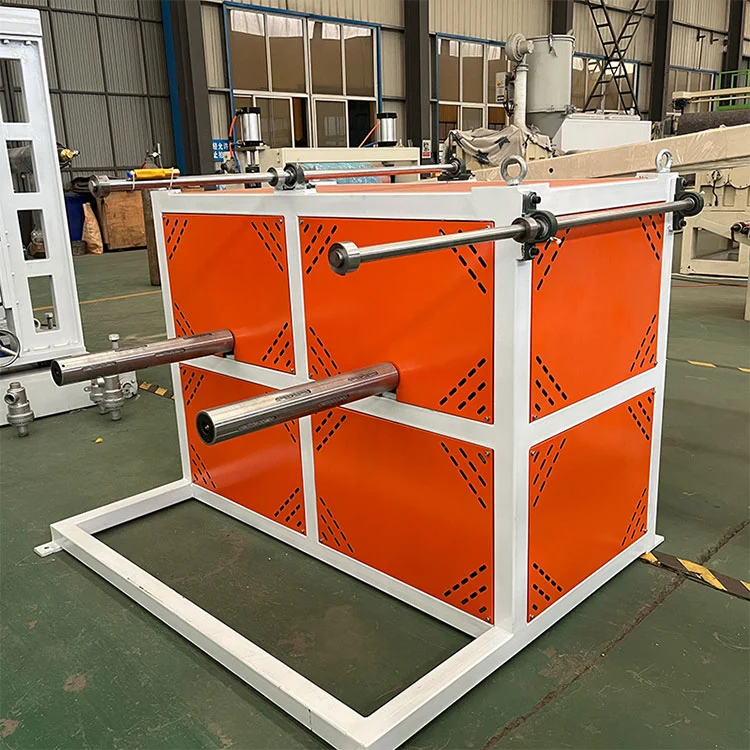

Welcome to the world of high-performance manufacturing with the PA Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This advanced machine is engineered to revolutionize your production line by delivering superior-quality polyamide (PA) sheets with unmatched precision, efficiency, and reliability. Whether you're in automotive, packaging, or industrial manufacturing, this extruder is designed to meet the demands of modern industries, ensuring consistent output for applications like automotive components, protective packaging, and technical parts. By integrating cutting-edge technology and robust design, it transforms raw materials into durable, high-strength sheets that enhance product performance and durability.

At the heart of this machine lies its exceptional core advantages. Constructed from premium-grade materials, it ensures long-lasting durability and minimal maintenance. The innovative extrusion technology guarantees uniform sheet thickness and optimal melt distribution, reducing waste and boosting productivity. User experience is prioritized with an intuitive control interface, allowing for easy adjustments and real-time monitoring. Backed by Qingdao Eaststar's stringent quality assurance, every machine undergoes rigorous testing to deliver consistent performance. This commitment to excellence means you can trust it for high-volume production without compromising on quality.

Many manufacturers face challenges like inconsistent sheet quality, high energy consumption, and frequent downtime. The PA Sheet Extruder Machine addresses these pain points head-on with smart solutions. For instance, its advanced heating system and precision screws ensure even material flow, eliminating defects. Coupled with energy-efficient motors, it cuts operational costs by up to 20%. To illustrate, here are key parameters that highlight its capabilities:

| Parameter | Value |

|---|---|

| Output Capacity | Up to 500 kg/h |

| Sheet Thickness Range | 0.5 mm to 10 mm |

| Power Consumption | 45 kW (average) |

| Heating Zones | 5 independently controlled zones |

| Machine Dimensions | Length: 8m, Width: 2.5m, Height: 3m |

This machine is ideal for a wide range of users, including industrial manufacturers, automotive suppliers, and packaging companies. In automotive settings, it produces robust components like engine covers and interior panels that withstand high temperatures and stress. For packaging, it creates strong, flexible sheets for protective wraps and containers. Technical part manufacturers rely on it for precision-engineered items in electronics and machinery. By catering to diverse scenarios, it supports businesses in scaling their operations while maintaining top-notch quality.

Using the PA Sheet Extruder Machine brings a sense of confidence and transformation. Imagine streamlining your production with fewer interruptions and higher yield—this machine makes it possible. It solves common issues like material waste and inconsistent output, leading to cost savings and enhanced product reliability. Users often report a boost in operational efficiency, allowing them to meet tight deadlines and expand their market reach. The emotional reward comes from knowing your products are built to last, fostering trust with clients and driving business growth.

What sets this extruder apart from competitors? Its unique integration of adaptive control systems and modular design allows for easy customization to specific material types, such as PA6 or PA66. Unlike standard models, it features a dual-stage cooling mechanism that ensures rapid solidification without compromising sheet integrity. Additionally, Qingdao Eaststar's dedicated support team provides comprehensive training and after-sales service, ensuring smooth integration into your workflow. These差异化亮点 make it a standout choice for those seeking innovation and reliability.

FAQ Section:

What types of PA materials can this machine process?

It handles various polyamide grades, including PA6, PA66, and reinforced composites, with adjustable settings for optimal performance based on material properties.

How does it ensure consistent sheet thickness?

Through precision screw design and automated feedback systems that monitor and adjust extrusion parameters in real-time, minimizing variations.

Is the machine easy to operate for beginners?

Yes, it features a user-friendly interface with touchscreen controls and pre-set programs, along with training resources from Qingdao Eaststar to facilitate smooth operation.

What maintenance is required?

Routine checks on screws and heating elements are recommended, with a maintenance schedule provided in the manual to ensure long-term reliability.

Can it be customized for specific production needs?

Absolutely, the modular design allows for upgrades like additional cooling units or specialized dies to match unique requirements.

How energy-efficient is it compared to other models?

It incorporates high-efficiency motors and insulation, reducing energy use by up to 25% over conventional extruders, as verified by industry tests.