PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

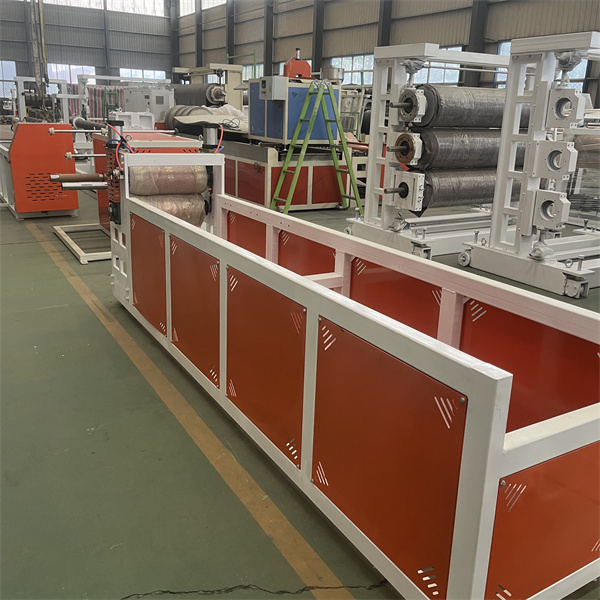

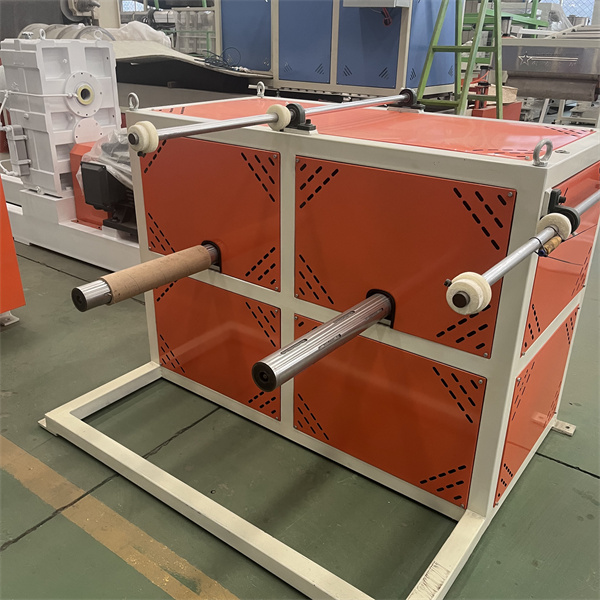

In the competitive landscape of industrial manufacturing, the demand for durable, high-performance plastic sheets has never been greater. Whether you're producing components for automotive interiors, medical equipment, or consumer electronics, the quality of your raw sheets directly impacts the final product's integrity and lifespan. The POK Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a testament to engineering excellence, designed to meet and exceed these rigorous demands. This advanced extrusion system is specifically tailored for processing Polyketone (POK) polymer, a material renowned for its exceptional strength, chemical resistance, and thermal stability. By integrating cutting-edge technology with robust design, this machine ensures that every sheet produced is of impeccable quality, paving the way for superior end-products in various high-stakes industries.

What sets the POK Sheet Extruder Machine apart is its holistic approach to performance and reliability. Crafted with precision, it incorporates a high-torque, energy-efficient drive system that minimizes power consumption while maximizing output consistency. The screw and barrel are constructed from bimetal alloys, offering exceptional wear resistance and extended service life, even when processing abrasive materials like POK. Furthermore, the machine features an intelligent temperature control system with multi-zone cooling, ensuring uniform heating and preventing material degradation. This results in sheets with consistent thickness, excellent surface finish, and minimal internal stress. Beyond technical specs, Qingdao Eaststar Plastic Machinery Co., Ltd. backs every unit with comprehensive quality assurance and responsive technical support, giving you peace of mind and minimizing downtime.

Manufacturers often face hurdles like inconsistent sheet quality, high energy costs, and frequent maintenance interruptions. The POK Sheet Extruder Machine is engineered to overcome these exact pain points. For instance, its advanced melt pump ensures precise pressure control, eliminating variations in sheet thickness that can lead to product rejects. The energy-saving design reduces electricity usage by up to 15% compared to conventional models, directly cutting operational expenses. Additionally, the easy-access maintenance panels and modular components simplify cleaning and part replacement, slashing downtime by over 30%. Below is a summary of key parameters that highlight its capability:

| Parameter | Specification |

|---|---|

| Screw Diameter | 65 mm - 120 mm (customizable) |

| L/D Ratio | 32:1 to 40:1 |

| Output Capacity | 200 - 800 kg/h |

| Heating Zones | 5 - 8 zones with PID control |

| Power Consumption | Optimized, 10-15% lower than industry average |

| Noise Level | <75 dB |

This machine is a perfect fit for manufacturers and fabricators who require high-performance plastic sheets for demanding applications. Industries such as automotive, aerospace, medical devices, and packaging benefit immensely from its output. For example, in the automotive sector, it produces robust sheets for fuel system components and interior trims that withstand extreme temperatures and chemical exposure. Medical device manufacturers use it to create sterile, high-strength sheets for surgical tools and equipment housings. Even consumer goods companies leverage its precision for creating durable electronic casings and appliance parts. Essentially, any business that prioritizes material integrity, production efficiency, and long-term cost savings will find the POK Sheet Extruder Machine an invaluable asset.

Imagine a production line where worries about sheet defects, machine breakdowns, and soaring energy bills are a thing of the past. Users of the POK Sheet Extruder Machine report a significant boost in operational confidence and overall productivity. The consistent quality of the extruded sheets reduces waste and rework, leading to faster turnaround times and higher customer satisfaction. Moreover, the machine's reliability means fewer interruptions for maintenance, allowing teams to focus on innovation and scaling their operations. This transformation isn't just about better equipment—it's about empowering your business to reach new heights of efficiency and quality.

While many extruders claim high performance, the POK Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. delivers tangible differences. Its unique screw design, optimized for POK's crystalline structure, ensures superior melting and mixing without shear degradation. The integration of IoT-ready sensors allows for real-time monitoring and predictive maintenance, a feature rarely found in standard models. Additionally, the machine's compact footprint and user-friendly interface make it accessible for both seasoned operators and new technicians. These innovations, combined with Eaststar's reputation for durable machinery, create a compelling value proposition that stands out from generic alternatives.

What maintenance schedule is recommended for this extruder?

Routine maintenance includes daily cleaning of the feed throat, weekly inspection of the screw and barrel for wear, and monthly calibration of the temperature controllers. The machine's design allows for easy access to critical components, reducing maintenance time. For optimal performance, we recommend a comprehensive service check every 1,000 operating hours.

Can the machine process materials other than POK?

Yes, the POK Sheet Extruder Machine is versatile and can handle other engineering plastics such as PEEK, PA, and PPS with minor adjustments to temperature profiles and screw speed. However, for best results with POK, we advise using the dedicated configuration to maximize material properties and output quality.

How does the energy-saving feature work?

The energy efficiency is achieved through a combination of an optimized screw design that reduces mechanical friction, high-efficiency AC motors, and intelligent heating zones that minimize heat loss. These elements work together to lower power consumption without compromising on output rates or sheet quality.

What kind of technical support is available after purchase?

Qingdao Eaststar Plastic Machinery Co., Ltd. provides comprehensive support including installation supervision, operator training, and 24/7 remote assistance. Spare parts are readily available, and our service team can be on-site if needed to ensure minimal disruption to your operations.

Is customization available for specific production needs?

Absolutely. We offer customization options for screw diameter, L/D ratio, output capacity, and control system upgrades. Our engineering team works closely with clients to tailor the machine to their unique material requirements and production goals.

What is the typical lead time for delivery and installation?

Standard models have a lead time of 4-6 weeks, while customized units may take 8-10 weeks. Installation typically requires 3-5 days, depending on site conditions. We coordinate closely with clients to schedule deliveries that align with their project timelines.