PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

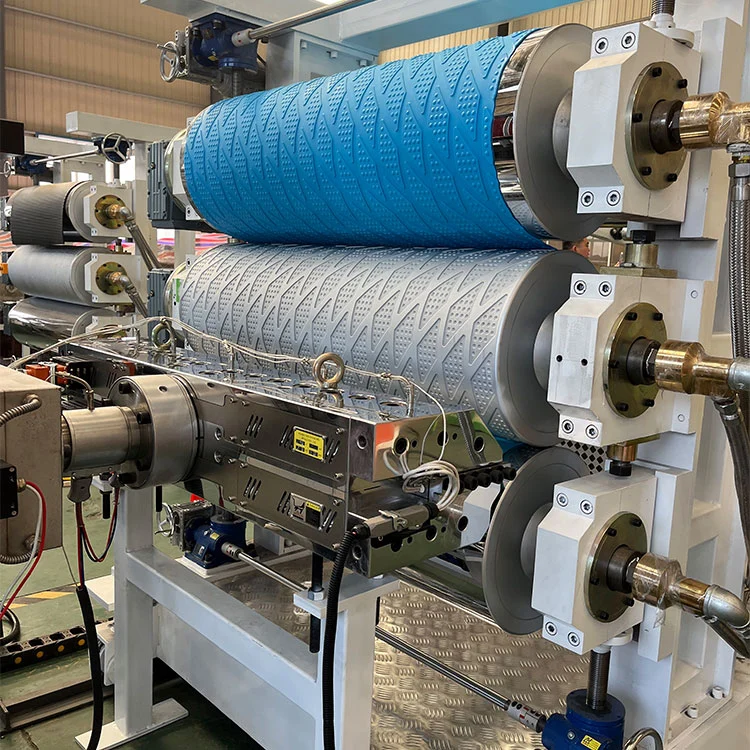

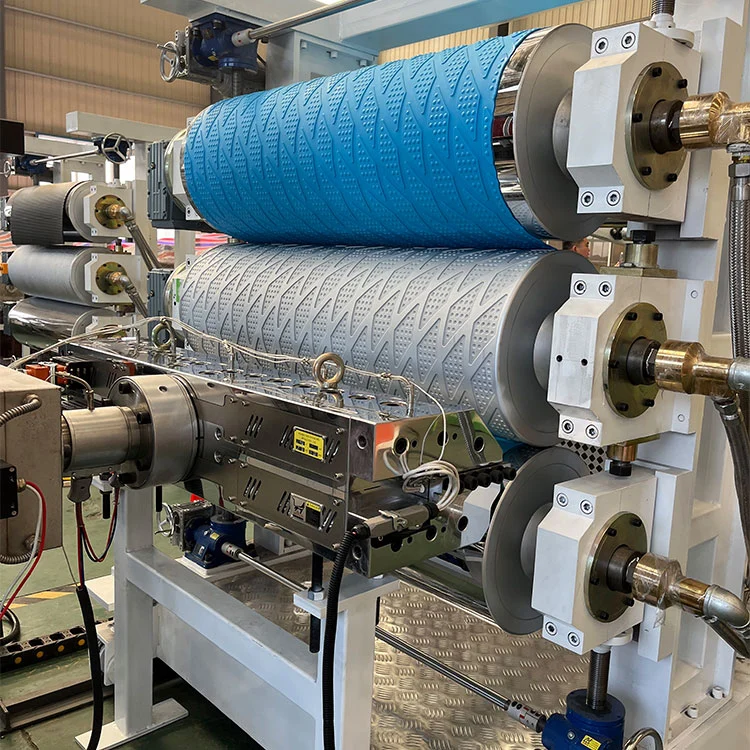

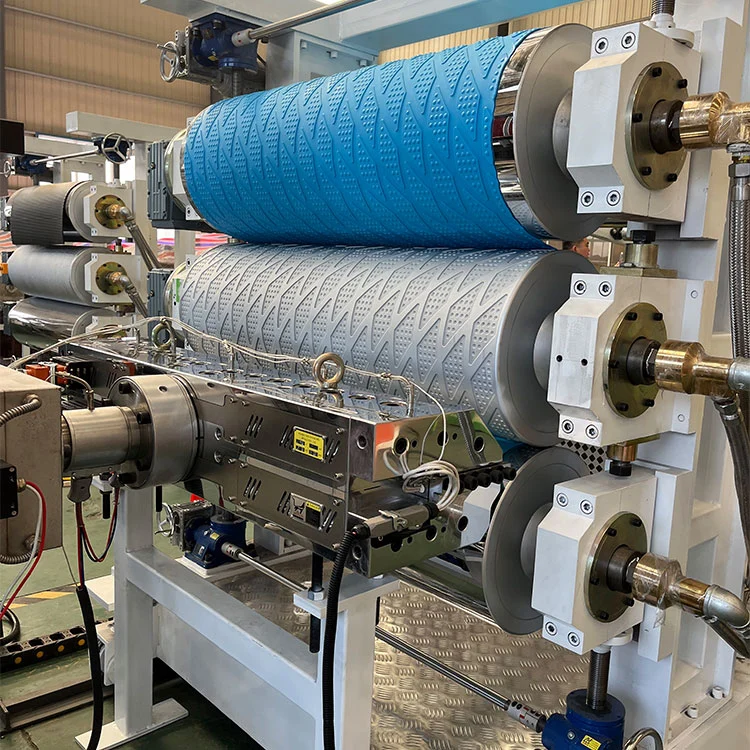

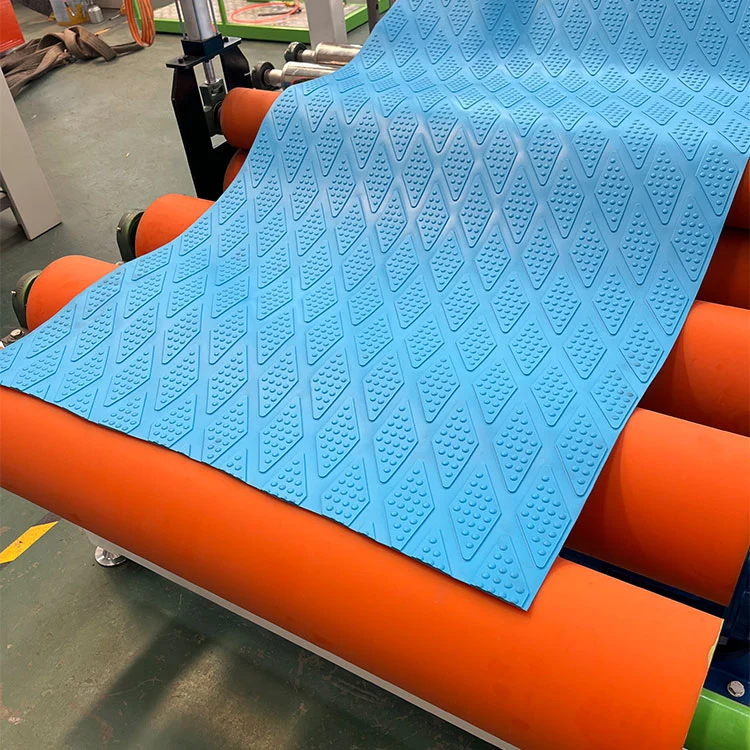

When it comes to manufacturing high-quality anti-slip mats, businesses demand machinery that delivers precision, efficiency, and reliability. The TPE TPV TPU TPR Anti-slip Mat Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. is engineered to meet these exacting standards. This advanced extruder is specifically designed for producing anti-slip mats using thermoplastic elastomers like TPE, TPV, TPU, and TPR, offering superior flexibility, durability, and safety features. Whether you are in the automotive, home goods, or industrial sectors, this machine provides a seamless solution for creating products that prevent slips and falls, enhancing user safety across various environments.

TPE TPV TPU TPR Anti-slip Mat Extruder Machine Overview">

TPE TPV TPU TPR Anti-slip Mat Extruder Machine Overview">

Imagine a production line where consistency and speed are paramount. Traditional methods often lead to material waste, uneven surfaces, and frequent downtime. The TPE TPV TPU TPR Anti-slip Mat Extruder Machine addresses these challenges head-on with its innovative design. It incorporates a high-precision screw and barrel system that ensures uniform melting and extrusion of materials, resulting in mats with consistent thickness and optimal anti-slip properties. This machine is not just about functionality; it’s about empowering manufacturers to produce mats that exceed safety standards while reducing operational costs. By integrating smart control systems, it allows for real-time adjustments, making it easier to switch between different materials like TPE, TPV, TPU, and TPR without compromising quality.

One of the standout features is its energy efficiency. In an era where sustainability is crucial, this extruder minimizes power consumption by up to 20% compared to conventional models, thanks to its optimized heating and cooling mechanisms. Additionally, the robust construction ensures longevity, with key components made from wear-resistant alloys that withstand high-temperature operations. This translates to fewer maintenance intervals and higher productivity over time. For businesses looking to scale their operations, the machine’s modular design allows for easy upgrades, ensuring it grows with your needs.

Who can benefit from this extruder? It’s ideal for manufacturers in sectors such as automotive interiors, where anti-slip mats enhance driver and passenger safety; home appliance producers creating non-slip liners for refrigerators or washing machines; and construction companies needing durable matting for wet or slippery surfaces. Even fitness centers and marine industries utilize these mats for their slip-resistant properties. The versatility of handling TPE, TPV, TPU, and TPR materials means you can tailor products to specific client demands, whether it’s for soft-touch household items or heavy-duty industrial applications.

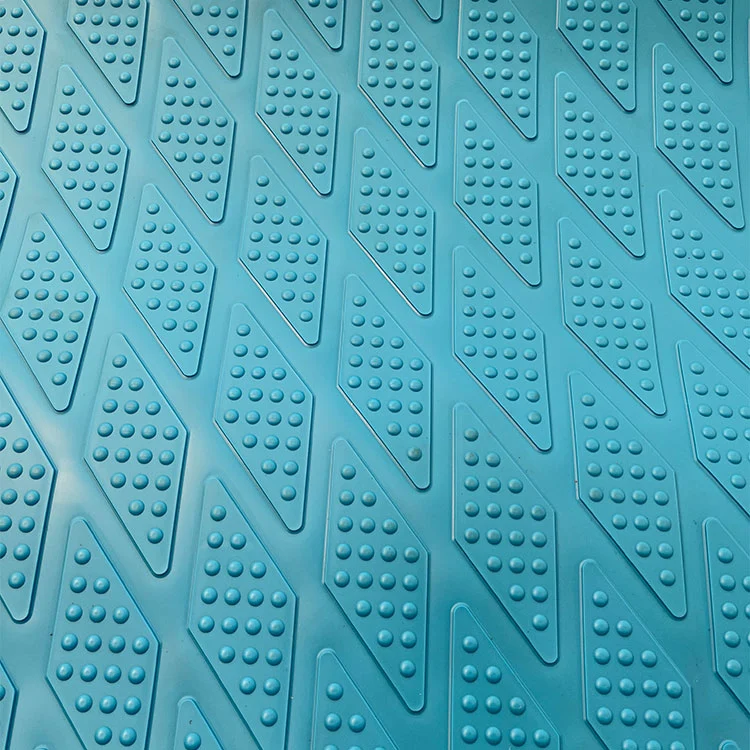

Consider a scenario in a busy factory where workers frequently encounter slippery floors, leading to accidents and lost productivity. With mats produced by this extruder, the textured surface provides reliable grip, even in oily or wet conditions. This not only safeguards employees but also boosts morale, as workers feel valued and protected. On an emotional level, using this machine instills confidence—knowing that every mat rolled out contributes to a safer environment. It solves the pervasive issue of workplace hazards while aligning with corporate responsibility goals.

What sets the Qingdao Eaststar Plastic Machinery Co., Ltd. extruder apart from competitors? First, its integrated digital control panel offers user-friendly operation, with touchscreen interfaces that display real-time data on temperature, pressure, and output speed. This reduces the learning curve for new operators and minimizes human error. Second, the machine supports a wide range of material blends, allowing for customization in hardness, color, and UV resistance. Unlike generic extruders, it includes an automatic cutting system that ensures precise mat dimensions, reducing post-production waste. Moreover, the company provides comprehensive after-sales support, including installation guidance and spare parts availability, which is a testament to their commitment to customer satisfaction.

To illustrate its capabilities, here’s a breakdown of common pain points and how this machine solves them, accompanied by technical parameters:

Pain Point: Inconsistent mat thickness leading to poor anti-slip performance.

Solution: The extruder’s precision gear pump and servo motor maintain stable output, ensuring uniform thickness across all production runs.

Technical Parameters:

| Parameter | Value |

|---|---|

| Screw Diameter | 65-120 mm |

| Output Capacity | 150-500 kg/h |

| Power Consumption | 15-45 kW |

| Heating Zones | 5-7 zones with PID control |

Pain Point: High energy costs and environmental impact.

Solution: Energy-efficient motors and insulation reduce electricity usage, while the machine’s compatibility with recycled TPE/TPR materials supports eco-friendly production.

Technical Parameters:

| Parameter | Value |

|---|---|

| Motor Type | AC frequency conversion |

| Cooling System | Water-cooled with temp control |

| Noise Level | <75 dB |

Beyond technical specs, the emotional impact is profound. Users report a sense of pride in producing mats that genuinely make a difference—whether it’s a family enjoying a slip-free bathroom or a worker navigating a greasy workshop safely. This machine transforms raw materials into life-enhancing products, fostering trust and loyalty among end-consumers. Its reliability means fewer production halts, allowing businesses to meet tight deadlines and expand their market reach confidently.

Frequently Asked Questions:

What materials can the TPE TPV TPU TPR Anti-slip Mat Extruder Machine process?

It efficiently processes thermoplastic elastomers including TPE (Thermoplastic Elastomer), TPV (Thermoplastic Vulcanizate), TPU (Thermoplastic Polyurethane), and TPR (Thermoplastic Rubber). These materials are chosen for their elasticity, weather resistance, and non-slip properties, making them ideal for various mat applications. The machine's screw design is optimized to handle different melt flow indexes, ensuring consistent quality even when switching between material types.

How does the machine ensure consistent anti-slip texture on mats?

Through a combination of precise temperature control and specialized die designs, the extruder creates uniform surface patterns that enhance grip. The integrated embossing system allows for customizable textures, from fine grains to coarse patterns, depending on the intended use. Real-time monitoring adjusts pressure to maintain texture integrity throughout production runs.

Is the machine suitable for small-scale manufacturers?

Yes, its modular design and scalable output make it adaptable for both small workshops and large factories. Optional features like semi-automatic controls can reduce initial investment, while still delivering high-quality mats. Qingdao Eaststar Plastic Machinery Co., Ltd. offers tailored solutions to match production volumes, ensuring accessibility for growing businesses.

What maintenance is required for long-term operation?

Routine maintenance includes cleaning the screw and barrel after material changes, inspecting heaters and sensors monthly, and lubricating moving parts every 500 hours of operation. The machine's durable components minimize wear, but following the provided checklist can extend its lifespan beyond 10 years. Support teams are available for scheduled servicing.

Can it integrate with existing production lines?

Absolutely. The extruder is designed with standard interfaces for conveyor belts, cutting units, and winding systems. Its compact footprint allows for easy placement in most setups, and technical assistance during installation ensures seamless integration with minimal disruption to ongoing operations.

How does the machine handle color changes or material blends?

The quick-purge screw design facilitates fast material transitions, reducing downtime between batches. For blended materials, a side feeder attachment can be added to mix additives like colorants or UV stabilizers uniformly, ensuring vibrant and consistent results across production cycles.

What safety features are included?

Standard safety measures include overload protection, emergency stop buttons, and thermal cut-offs to prevent overheating. The enclosure design reduces operator exposure to moving parts, and optional safety guards can be added for compliance with international workplace standards.

Does Qingdao Eaststar provide training for operators?

Yes, comprehensive training programs cover machine operation, troubleshooting, and basic maintenance. These are available on-site or through virtual sessions, empowering your team to maximize productivity and minimize errors from day one.

In summary, the TPE TPV TPU TPR Anti-slip Mat Extruder Machine is more than just equipment; it’s a partnership in innovation. By choosing Qingdao Eaststar Plastic Machinery Co., Ltd., you invest in a future where safety, efficiency, and quality converge. Explore the possibilities and elevate your production capabilities with a machine that understands the nuances of modern manufacturing.